Creating a Hierarchical Asset Register using AI

No company can afford to neglect the technological advancements catapulting us towards Industry 4.0. For a facility, the foundation for 4.0 is establishing a hierarchical asset register, but much of the required data is unstructured and locked in scanned documents. Manually sorting, extracting, and packaging that data into a usable format is an intractable task.

It doesn’t have to be that way: Artificial Intelligence (AI) can accomplish what’s required in a fraction of the time, and propel you towards your ultimate goal of improving O&M. If you’re unfamiliar with the technology though, it can be challenging to implement it for the correct tasks. Plus, how can you be sure whether to trust the results? It’s often a blackbox, after all. You want to bring humans into the loop for quality control, but aren’t sure of where they should come into the workflow.

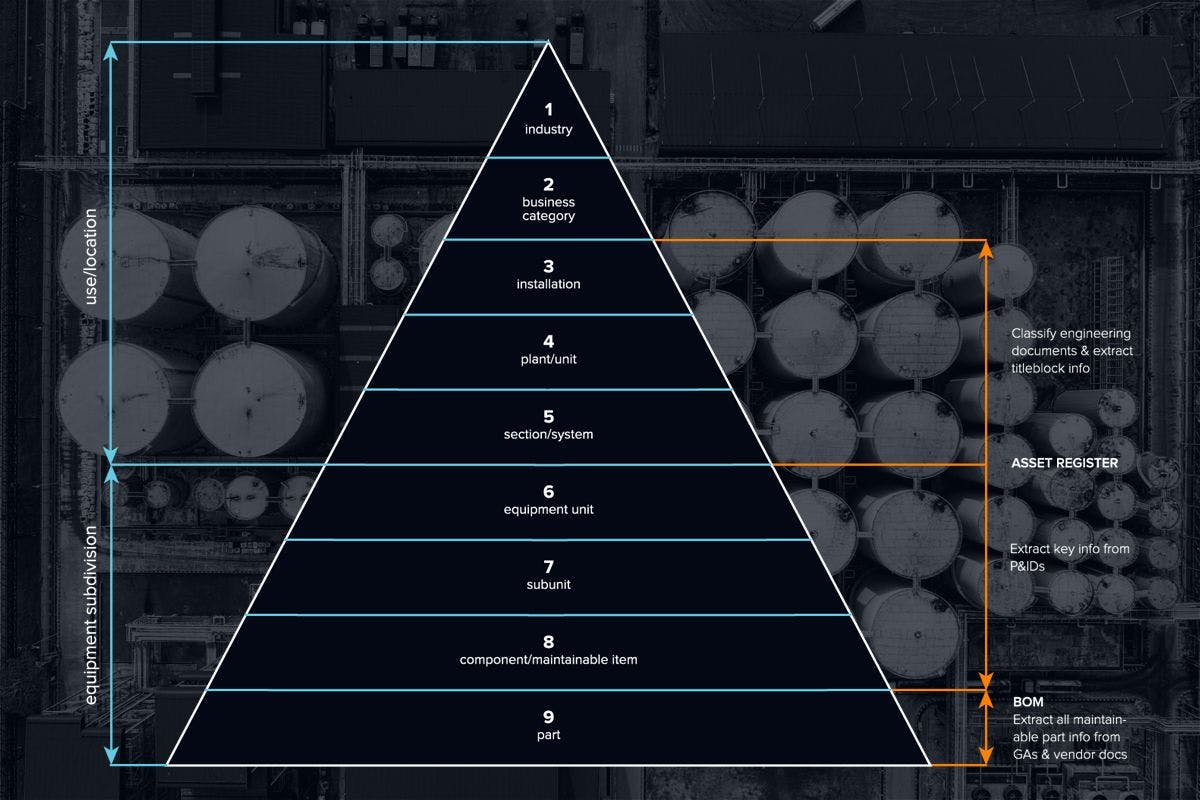

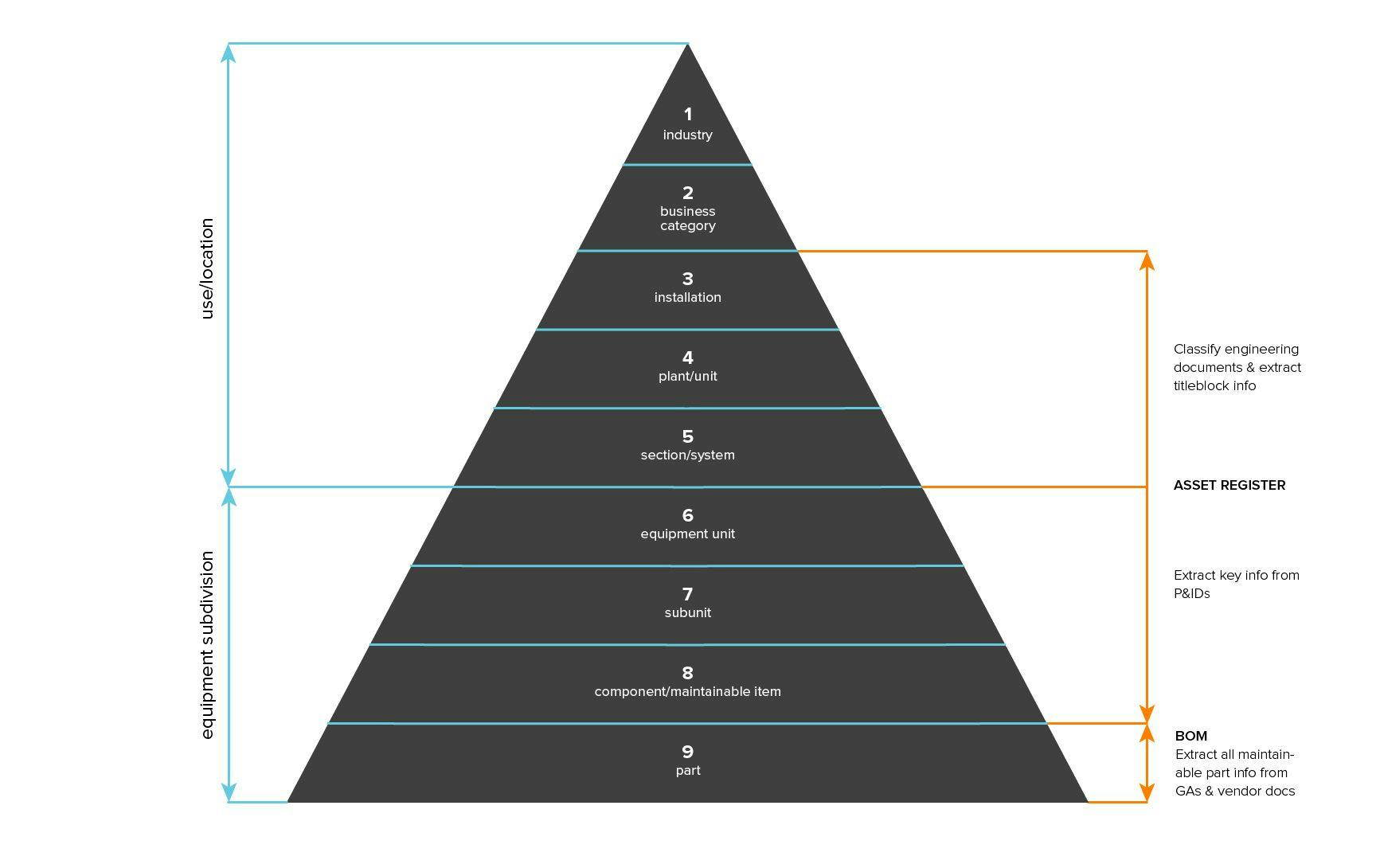

In this guide, we’ll help you lay out a machine-human framework to build a hierarchical asset register based on the ISO 14224:2016 standard.

Key steps in the machine-human framework corresponding to the ISO 14224 parent-child relationship

What’s in your data repo?

First things first: Sort out that information before sending anything for extraction. Why? You may have a couple million files in your repository, but how many are actually relevant? You’ll find tons of photos and other random documentation that you don’t need to process. Once that’s trimmed down, you then want to quickly categorize the remainder because some documents and drawings, such as P&IDs, are of higher priority than others. All of this should be done using AI, because there’s just too much data to sort through.

Populate ISO 14224 levels 3-5

Once your data is sorted, it’s time to tackle ISO 14224 levels three to five—you will need to extract data about installation, plants/units, and systems. All the information you’re looking for resides in the title blocks of engineering drawings:

- Bring in the machine

* Reorient rotated drawings

* Correct scanning skew

* Detect the title block

* Identify each cell in the title block and extract text with OCR

* Analyze the text from each cell using Natural Language Processing (NLP)

* Automatically populate the appropriate fields in your asset register - Bring in the human

* Design your asset register

* Feed all engineering drawings into your data pipeline

* Check documents that the machine registers with low confidence

* Correct OCR errors for important fields

Populate ISO 14224 levels 6-8

The next step is to gather context about equipment, instrument loops, and maintainable components from your P&IDs.

- Bring in the machine

* Use AI to detect and extract:

* Instrument tags

* Valve tags

* Line numbers

* Equipment numbers

* Use AI to analyze and predict instrument loops, then link those instrument loops, safety valves, and other components to their parent equipment

* Automatically populate your hierarchical asset register - Bring in the human

* Correct OCR errors—it’s very important that your tags are captured accurately. Even state-of-the-art OCR often confuses certain characters like “1” and “l” or “8” and “b” depending on your document quality

* Correct instrument loop prediction errors

Building your Bill of Materials (ISO 14224 level 9)

Finally, you need to generate an aggregated Bill of Materials (BOM) that links to the rest of the asset register.

- Bring in the machine

* Use NLP to rapidly analyze millions of pages and only flag the ones pertaining to parts information

* Detect and extract tabular information for parts with a combination of computer vision and NLP algorithms, and export each table into an editable spreadsheet for humans to review later

* Normalize header names such as “part” or “item,” which refer to the same type of data

* Automatically populate your BOM template - Bring in the human

* Design your aggregated BOM template

* Verify detected tables and add any that the machine missed

* Correct OCR errors

Consolidating the machine-human framework

Bringing AI into this unstructured data extraction exercise introduces many new steps, but ultimately accelerates the entire process significantly, simply because machines can process such huge volumes of data more efficiently than humans. They’re not perfect though, so bringing a human into the loop is essential if you’re looking for 100% accuracy.

Nevertheless, adding AI to the flow also presents new challenges, such as building out data pipelines, identifying and designing the correct machine learning algorithms, dealing with various export formats, and porting data back and forth between the algorithms and spreadsheet software like Excel so that your team can remediate errors. To address these pain points, Cenozai develops systems of intelligence to stitch all of these pieces together into a comprehensive workflow so you and your team can hit the ground running. Our Facility Maintenance SOI supports your team through levels three to nine of ISO 14224, all in a single interface that’s designed for seamless human and machine collaboration. For more information, feel free to contact us.

Recommended Posts

8/15/2024

A new era of enterprise search for facilities

(Part II): Data preparation

Before implementing new search technology, data cleanup and preparation is critical. Here's what you need to do.

8/1/2024

A new era of enterprise search for facilities

Enterprise search is changing for facility operators—out with the file hierarchies and in with the information networks.

12/16/2022

Industry 4.0: The Unstructured Data Perspective

How to build a contextual platform that will be the launching pad for every one of your Industry 4.0 initiatives.