Legacy Data Transformation

The first step towards digital transformation for an asset intensive facility is establishing the physical and operating context of its assets. Cenozai's AssetBot, comprising three modules, is designed according to ISO14224:2016, but reconfigurable to other frameworks.

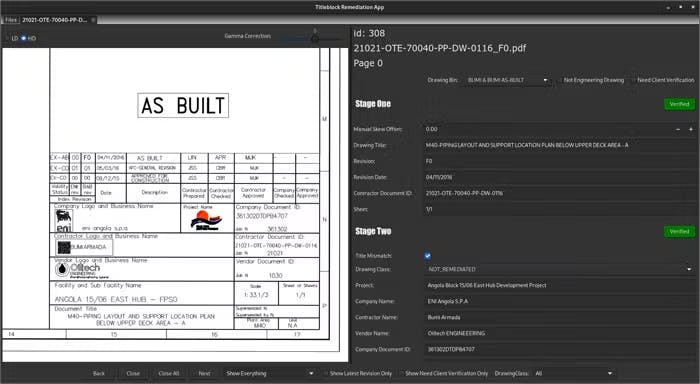

Site Register

- Extract data from title blocks of engineering drawings to populate levels 1-5 of ISO14224

- Create a drawing register

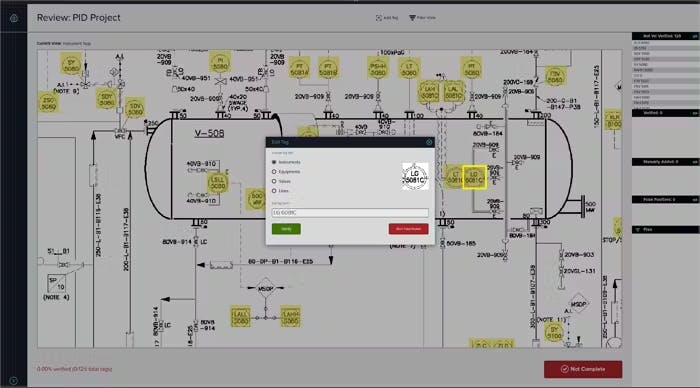

Equipment Register

- Extract equipment, instrument and cable IDs from scanned P&IDs and SLDs

- Hot-spot critical components to quickly access key data directly from drawings

- Organize IDs hierarchically

BOM Generation

- Rapidly find parts information spread throughout hundreds of thousands of pages of vendor documents

- Convert scanned tables to Excel